From the outer packaging of a pack of tissues to the outer parts of a car, plastic products are widely used in daily life. In recent years, the plastic industry has been empowered by technological innovation, and has continuously upgraded to higher-end, greener, and smarter manufacturing, with a strong momentum of sustainable development.

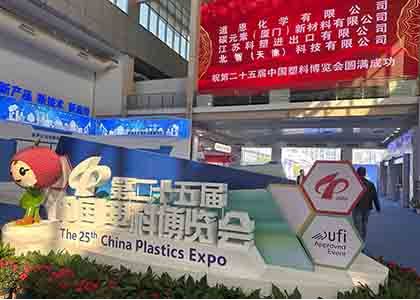

On October 19, the 25th China (Taizhou) Plastics Industry Expo 2024 opened at the Taizhou International Convention and Exhibition Center. This exhibition lasted for 3 days, with the theme of "low carbon, recycling, and smart manufacturing", attracting more than 600 upstream and downstream companies in the plastic industry from all over the country to participate in the exhibition, focusing on displaying new products, new technologies, new equipment, and new achievements, and fully empowering the innovation and development of the plastic industry.

At the exhibition site, a fully automated wide-mouth bottle production line of Beizhi attracted onlookers. The production workers only need to add raw materials, and after a series of complex procedures and processes, transparent and three-dimensional wide-mouth bottles are output at a uniform speed along the production line. "This wide-mouth bottle blowing machine adopts a microcomputer control system, which greatly liberates manpower, is simple and convenient to operate, and the production process is fully automated." The on-site staff introduced that this machine is suitable for blowing plastic containers of various shapes such as carbonated beverage bottles, mineral water bottles, pesticide bottles, cosmetic bottles, and medicine bottles made of PET/PC/PP/PE.

There are also horizontal, vertical, and oblique arm mechanical arms that realize the full automation of the injection molding industry, which are operating efficiently, and simulation robots are busy on the production line; various self-supporting zipper bags and three-side sealed zipper bags jump out of the intelligent bag making machine. Digital applications have driven the plastic industry to develop towards intelligence.

Circular low-carbon and greening have always been important directions for the transformation and upgrading of the plastic industry. In front of the exhibition area dominated by environmentally friendly packaging and plastic recycling, the colorful and different styles of packaging boxes are dazzling. "This is our environmentally friendly carbon-based plastic box. It uses plastic instead of wood and paper. It is a more practical new type of degradable environmentally friendly material." The staff said that compared with traditional packaging boxes, it has more functions, is waterproof and moisture-proof, wear-resistant and shock-resistant, and most importantly, it is recyclable, which can be recycled and reused, energy-saving and environmentally friendly. It is currently widely used in the transportation packaging of fruits and vegetables, frozen fresh food, food import and export and other products.

Focusing on special use, the functionalization of plastic packaging continues to increase. The packaging of vacuum-extracted foods should have the advantages of good transparency, high gloss, and good flexibility; the packaging of frozen foods should have both softness and puncture resistance to avoid low-temperature cracking and bag breakage; the packaging of clothing, hotel daily chemicals, and electronic products should have single-sided matte, good flatness, good tensile strength and other properties...